Six Innovations That Could Eradicate Plastic Forever

As I walked along the beach, I couldn’t help but notice how much it had changed. The stunning view of the sunset stood above the horizon as a fierce ball of fire amidst the serenity of the slowly ascending waves colored by the warm tones of the evening sky. However, a turn towards the shore broke my heart and destroyed the sooth that nature had surrounded me with. Bottles, wrappers, straws and fishing nets mindlessly thrown away and people blindly walking over them with no thought of its detriment.

80% of the marine debris is currently plastics. This poses great threat to marine life because when it is consumed, they are broken down as toxins causing health issues that contain a risk of being transgenerational. This affects generations of the marine species, leading them to eventual extinction. Another major result of plastic pollution is marine life entanglement already endangered species such as turtles that greatly contribute towards the balance of our ecosystem. Plastic is also a contaminant that has the power to alter natural food chains and introduce new invasive species to a balanced ecosystem. But, since its discovery in the 1900s, we have grown too dependent on its favorable properties such as its hardiness, durability, and waterproof nature. When I look at my desk space, I could count up to 8 items made of plastic. Living plastic-free seems to be a mission.

Here’s a silver line of hope that this mission may in fact be possible, thanks to new technological advancements that offer alternative solutions to traditional plastic. In this article, we will explore five innovative technologies that have the potential to eradicate the need for plastic altogether, leading us towards a sustainable and environmentally-friendly future.

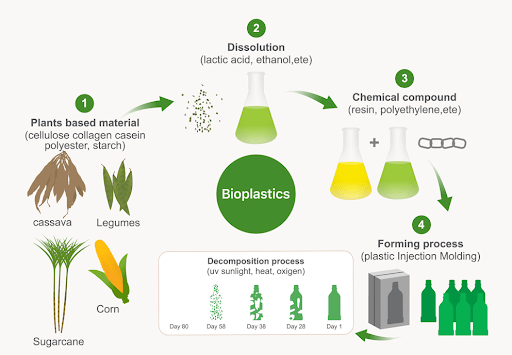

- Biodegradable plastics (bioplastics)

Bioplastics are environmentally friendly material manufactured using botanical and microbial sources. This material takes three to six months to degrade when compared to polyethylene derivatives which takes over a century. The material is currently under research to improve mechanical properties and malleability. The study conducted by the University of Pittsburgh shows that biopolymer exhibit relatively high ranking in terms of green design, high environment impact from production when compared to petroleum polymer [1]. When speaking of their functionality, the use of polybutylene increases their half-life and prevents antecedent biodegradation [2].

Figure 1: Process of making bioplastics

(Source: University of Minnesota Institute of the Environment)

- Mycelium packaging (mushroom packaging)

This is a novel technology that uses the fibers of fungi known as mycelium to produce alternative plastic. Since mycelium forms a thick network of varying shape and size, it can be manipulated and structured to our need. Furthermore, it’s insulating properties are an added bonus. In nature, mycelium grows underground and on tree trunks. For industrial purposes, mycelium can be cultivated on agricultural wastes under regulated conditions. This way, it is extra eco-friendly as it follows the zero waste policy! The drawbacks of mycelium are that it is easily contaminated and quick to form molds. Therefore, it is not practical for long-term use. To add, its production cost is fairly higher than traditional plastic, making it less desirable for manufacturers. However, recent research has constructed cotton-based mycelium that has an increased viability [3]. With further refinements in this material, it is sure to be a guaranteed replacement for plastics.

Figure 2: Mycelium packaging created for luxury perfume

(Source: Vogue)

- Edible packaging

Consumable plastics shook the media a few years back. This single-use plastic got a lot of attention due to the bizarreness of consuming the package along with whatever food or drink it carries. Edible plastic is made from kelp or polymeric carbohydrate. The unique property of edible plastics is its water-proof nature. Since it is able to prevent moisture loss, flavors of food will not be lost by evaporation [6]. Recently, probiotic-based plastic was developed using bacteria. This was intended to be used in place of plastic wraps that are used to coat vegetables. Apart from preserving the freshness of vegetables, it additionally delivers extra nutritional benefits! [7] However, its poor tensile strength and water solubility needs to be resolved for its applications to be expanded.

Figure 3: Water pods made of edible packaging

Source: The Guardian

- Cellulose-based plastic

This alternative to plastics is made from an organic compound obtained from plants, algae, fungi and some bacteria. Cellulose is a component of the cell walls of plants and microorganisms. Once the material is isolated it can be made into films and coats that are durable packaging materials that have minimal water permeability. The drawback of cellulose-based items is their poor tensile strength [8]. To address this issue, acetylated cellulose nanocrystals were developed. These have excellent tensile strength but their tensile strength declines when atmospheric moisture increases. Therefore, currently it is only suitable for packaging dry products [9].

Figure 4: Process of making cellulose-based plastics

Source: American Chemical Society

- Natural fiber packaging

Natural fiber, one of the oldest packaging materials is obtained from fiber-rick plants such as hemp, flax or bamboo. Let not their lightweight deceive you. Their mechanical strength is extraordinary. What makes them more desirable than other plastic alternatives is their inferior fire resistance, malleability, and high moisture absorption rates. However, their durability is questionable and their affinity for water limits their commercial application [10].

Figure 5: Packaging made of natural fiber

Source: International fiber journal

- Beeswax wraps

Beeswax wraps are made from materials such as cotton, beeswax, resin and jojoba oil. Due to their malleability, they can be molded around containers and food items, creating a customized fit. Unlike many other plastic alternatives, beeswax wraps can be cleaned and reused. Moreover, their breathability helps extend the freshness of perishables and reduces food wastes. Manufacturers are continuously working to improve the formula of beeswax wraps. Some improvements include enhanced adhesiveness to containers and food items and heat tolerance. Currently scientists are trying to resolve the drawback of low airtightness [11].

Figure 6: Food being packaged with beeswax wraps

Source: Country living

Despite ecofriendly alternatives being introduced, the World has not yet realized the urgency to mitigate the environmental impacts of traditional plastics. Cost concerns and convenience are major reasons why the demand for plastic alternatives are low. Research and innovative solutions are not enough to overcome these barriers. Education regarding environmental sustainability and policy changes are important for these innovations to be standardized in the real world.

Faisal Shamim Khan, Esther Swamidason

References:

1. Tabone D.M., Cregg J.J., Beckman E.J. et al. Sustainability metrics: Life cycle assessment and green design in polymer. Environmental Science & Technology. 2010 44 (21): 8264-8269: https://pubs.acs.org/doi/10.1021/es101640n#

2. Lott C., Eich A., Makarow D. et al. Half-Life of Biodegradable Plastics in the Marine Environment Depends on Material, Habitat, and Climate Zone Front. Marine Science. 2021 May: 8. https://www.frontiersin.org/articles/10.3389/fmars.2021.662074/full

3. Holt G. A., Mcintyre G., Flagg D. et al. Fungal Mycelium and Cotton Plant Materials in the Manufacture of Biodegradable Molded Packaging Material: Evaluation Study of Select Blends of Cotton Byproducts Journal of Biobased Materials and Bioenergy. 2012 Aug: 6(4):

6. Iversen L.J.L, Rovina K., Vonnie J.M et al. The Emergence of Edible and Food-Application Coatings for Food Packaging: A Review. Molecules. 2022, 27, 5604:

7. Iseppi R., Zurlini C., Cigognini, I.M et al. Eco-Friendly Edible Packaging Systems Based on Live-Lactobacillus kefiri MM5 for the Control of Listeria monocytogenes in Fresh Vegetables. Foods 2022, 11, 2632:

8 Qasim U., Osman A.I., Al-Muhtaseb A.H et al. Renewable cellulosic nanocomposites for food packaging to avoid fossil fuel plastic pollution: a review. Environmental Chemistry Letters 2021, 19, 613-641: https://link.springer.com/article/10.1007/s10311-020-01090-x

9. Oberlintner A., Likozar B., Novak U. Effect of Environment on Acetylated Cellulose Nanocrystal-Reinforced Biopolymers Films. Polymers 2023, 15(7), 1663:

10. Azman M.A., Asyraf M.R.M., Khalina A. et al. Natural Fiber Reinforced Composite Material for Product Design: A Short Review. Polymers 2023, 13(12): 1917: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8228744/ 11. Szulc, J., Waldemar Machnowski, Kowalska, S., Jachowicz, A., Ruman, T., Aleksandra Steglińska, & Gutarowska, B. (2020). Beeswax-Modified Textiles: Method of Preparation and Assessment of Antimicrobial Properties. Polymers, 12(2), 344–344. https://doi.org/10.3390/polym12020344